PRODUCTS

Chinese Standard Rolling Stock Cables

- Super-thin Wall Multicore Cables

DT-RFE 750V

Application :

- -Used as power and control cable for protected installations inside and outside of rail and transport vehicles, where

handling and installation cost are an important factor.

-Used in control, auxillary and main circuit wiring such as cable harnesses, switchboards and control panels, driver desks etc.

Construction :

-

Conductors Tinned copper wires Insulation Electron beam crosslinkable LSZH compound Sheath TPU plastic sheath -

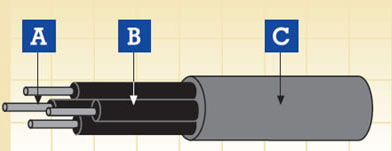

A. Conductor B. Insulation C. Sheath

Electrical & Mechanical Properties :

-

-

Nominal Voltage 750V Short Circuit Temperature (5s) 250°C Operating Temperature -60°C/+125°C Minimum Bending Radius 3 x Overall Diameter (OD≤20mm); 5 x Overall Diameter (OD≥20mm)

Fire Performance :

-

Flame Retardant GB 12666-90 DZ-1 Low Corrosivity (Acidity & Conductivity) GB/T17650.1-1998; GB/T17650.2-1998 Halogen Free GB/T17650.1-1998; GB/T17650.2-1998 Low Smoke GB/T17651.1-1998; GB/T17651.2-1998

DT-RFE 750V :

-

Number of

conductor×Nominal Cross-Sectional AreaConductor Construction Maximum Overall Diameter Weight Maximum Conductor Resistance

20°Cmm² No/mm mm kg/km Ω/km 2×0.5 19/0.18 3.84 34.0 40.1 3×0.5 19/0.18 3.97 42.5 40.1 4×0.5 19/0.18 4.60 53.5 40.1 5×0.5 19/0.18 4.82 68.1 40.1 6×0.5 19/0.18 5.06 70.5 40.1 7×0.5 19/0.18 5.40 79.0 40.1 8×0.5 19/0.18 5.96 90.5 40.1 2×0.75 19/0.23 4.14 39.0 26.7 3×0.75 19/0.23 4.71 53.5 26.7 4×0.75 19/0.23 5.16 66.0 26.7 5×0.75 19/0.23 5.56 77.8 26.7 6×0.75 19/0.23 5.76 92.8 26.7 7×0.75 19/0.23 6.15 104.0 26.7 8×0.75 19/0.23 6.76 117.0 26.7 2×1.0 19/0.26 4.38 45.0 20.0 3×1.0 19/0.26 5.00 63.0 20.0 4×1.0 19/0.26 5.51 77.5 20.0 5×1.0 19/0.26 5.96 93.0 20.0 6×1.0 19/0.26 6.26 111.5 20.0 7×1.0 19/0.26 6.60 126.0 20.0 8×1.0 19/0.26 7.36 143.0 20.0 2×1.5 19/0.32 5.04 52.5 13.7 3×1.5 19/0.32 5.88 82.5 13.7 4×1.5 19/0.32 6.14 105.5 13.7 5×1.5 19/0.32 6.96 120.0 13.7 6×1.5 19/0.32 7.56 144.75 13.7 7×1.5 19/0.32 7.80 164.5 13.7 8×1.5 19/0.32 8.46 185.0 13.7 2×2.0 19/0.37 6.10 63.7 10.0 3×2.0 19/0.37 6.41 94.7 10.0 4×2.0 19/0.37 7.14 122.5 10.0 5×2.0 19/0.37 8.14 152.2 10.0 6×2.0 19/0.37 8.65 181.9 10.0 7×2.0 19/0.37 8.86 210.7 10.0 8×2.0 19/0.37 9.56 240.4 10.0 2×2.5 19/0.41 6.60 77.5 8.21 3×2.5 19/0.41 7.16 118.0 8.21 4×2.5 19/0.41 8.06 142.5 8.21 5×2.5 19/0.41 9.06 169.0 8.21 6×2.5 19/0.41 9.77 213.2 8.21 7×2.5 19/0.41 10.26 240.0 8.21 8×2.5 19/0.41 11.26 280.0 8.21 2×4.0 19/0.52 7.70 111.0 5.00 3×4.0 19/0.52 8.21 160.65 5.00

|

|

|

|

|

|

Corona Resistant |

Highly Flexible |

UV Resistant |

Ozone Resistant | Abrasion Retardant |

Cold- resistant |

|

|

|

|

|

|

Resistance To Soldering Heat |

Acid&Alkaline Resistant |

IRM 903 Fuel Oil Resistant |

IRM 902 Mineral Oil Resistant |

Fire Retardant NF C32-070-2.2(C2) IEC60332-3-24/EN50266-2-4 |

Flame Retardant NF C32-070-2.1(C1) IEC60332-1-2/EN50265-2-1 |

|

|

|

|

Low Toxicity NF X70-100/NF F63 808 TM1-04/BS 6853 |

Low Corrosivity IEC60754-2/EN50267-2-2/3 NF C32-074/VDE 0472-813 |

Low Smoke Emission IEC 61034-2 / EN 50268-2 NF C32-073/VDE 0472-816 |

Zero Halogen IEC 60754-1/EN 50267-2-1 NF C32-074//VDE 0472-815 |