PRODUCTS

EN 50264 Medium Wall Power & Control Cable

- FIREROL Medium Wall Single Core Screened & Sheathed Cables 1.8/3 kV or 3.6/6 kV

EN 50264-3-1 (FRL-MW-3S-OS, FRL-MW-6S-OS)

APPLICATION

- -Used as power and control cable for protected installations inside and outside of rail and transport vehicles, where handling and installation cost are an important factor.

- -Used in control, auxillary and main circuit wiring such as cable harnesses, switchboards and control panels, driver desks etc.

Construction :

-

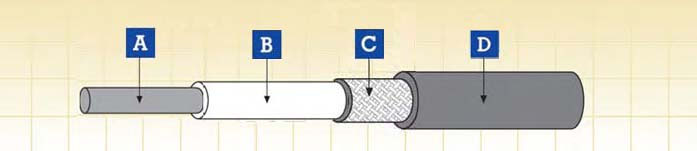

Conductor Flexible tinned annealed copper wires, stranded as per HD 383 (IEC 60228) class 5 Insulation LSZH elastomeric compound as defined in EN 50264-1 (EI 106 to EI 109) Overal screen Tinned annealed copper wires Sheath LSZH elastomeric compound as defined in EN 50264-1 (EM 101 to EM 104) -

A. Conductor B. Insulation C. Screen D.Sheath

Electrical & Mechanical Properties :

-

Nominal Voltage 1.8/3 kV or 3.6/6 kV Maximum Conductor Temperature 90°C ( fixed installation ) Minimum Permissible Ambient Temperature -25°C/-40°C ( fixed installation ) Bending Radius 3 x Overall Diameter (D<12mm); 4 x Overall Diameter (D>12mm)

Chemical & Environmental Properties :

-

EN 60684-2 No fluorine EN 50305; EN 60811-2-1 Resistance to mineral oil & fuel oil, acid & alkali EN 50305 Resistance to ozone

Fire Performance for rolling stock application :

-

EN 50306-2 Hazard levels HL1, HL2/HL3, HL4 DIN 5510-2 Protection level 1/2/3/4 BS 6853 Interior use 1a, 1b, II; Exterior use 1a, 1b, II NF F 16-101 F0 EN45545-2 R15 Interior/ R16 Exterior HL1, HL2, HL3

Fire Performance in General :

-

EN 50265-2-1; IEC 60332-1-2; NF C 32-070 2.1 (C2) Vertical flame propogation for a single insulated wire or cable EN 50266-2-4 + EN 50305; IEC 60332-3-24;

NF C 32-070 2.2 (C1); VDE 0472 Teil 804Vertical flame spread of vertically mounted bunched wires or cables EN 50268-2; IEC 61034-2; NF C 32-073 ;

NF C 20-902; NF F 16 101; VDE 0472 Teil 816Low Smoke Emission EN 50267-2-1; IEC 60754-1; NF C 32-074;

NF C 20-454; VDE 0472 Teil 815Halogen Free EN 50267-2-2/3; IEC 60754-2; NF C 32-074;

NF C 20-453; VDE 0472 Teil 813

Low Corrosivity (Acidity & Conductivity) EN 50305; NF X 70-100; NF F 63 808; TM1-04; BS6853 Low Toxicity NF F 63 808; BS6853; NF F 16 101 Smoke index EN45545-2 Requirement for fire behavior of materials & components R15/R16

FRL-MW-3S-OS 1.8/3 kV :

-

Nominal

Cross-Sectional

AreaConductor

Diameter

(a)Min. Mean

Thickness

of InsulationMin. Screen Wire Diameter Min. Mean

Thickness

of SheathOverall

DiameterWeight Conductor

ResistanceInsulation Resistance min max 20℃ 20℃ 90℃ mm2 mm mm mm mm mm mm kg/km Ω/km MΩ x km MΩ x km 1.5 1.5 1.3 0.8 0.16 6.6 7.6 103 13.7 21.8 0.218 2.5 1.95 1.3 0.8 0.16 6.9 8.1 123 8.21 18.8 0.188 4 2.5 1.3 0.8 0.21 7.5 8.8 157 5.09 16.2 0.162 6 3.0 1.3 0.8 0.21 7.9 9.4 189 3.39 14.4 0.144 10 3.9 1.5 0.8 0.21 9.1 10.8 264 1.95 12.8 0.128 16 5.0 1.5 0.8 0.26 10.2 12.0 359 1.24 10.7 0.107 25 6.4 1.8 1.0 0.26 12.1 14.2 510 0.795 10.3 0.103 35 7.7 1.8 1.0 0.31 13.3 15.2 650 0.565 8.9 0.089 50 9.2 1.8 1.0 0.31 14.7 16.8 846 0.393 7.8 0.078 70 11.0 1.8 1.0 0.31 16.6 19.3 1130 0.277 6.7 0.067 95 12.5 2.2 1.0 0.31 18.7 21.1 1436 0.210 6.5 0.065 120 14.2 2.2 1.0 0.31 20.6 23.0 1765 0.164 6.1 0.061 150 15.8 2.2 1.2 0.31 22.0 25.3 2128 0.132 5.8 0.058 185 17.5 2.4 1.2 0.31 24.0 29.0 2541 0.108 5.6 0.056 240 20.1 2.4 1.2 0.31 26.8 30.5 3244 0.0817 5.0 0.050 300 22.5 2.4 1.2 0.31 29.2 33.0 3934 0.0654 4.5 0.045 400 25.8 2.6 1.4 0.31 32.9 38.0 5078 0.0495 4.4 0.044

FRL-MW-6S-OS 3.6/6 kV :

-

Nominal

Cross-Sectional

AreaConductor

Diameter

(a)Min. Mean

Thickness

of InsulationMin. Screen Wire Diameter Min. Mean

Thickness

of SheathOverall

DiameterWeight Conductor

ResistanceInsulation Resistance min max 20℃ 20℃ 90℃ mm2 mm mm mm mm mm mm kg/km Ω/km MΩ x km MΩ x km 2.5 1.95 2.6 0.8 0.16 9.6 10.7 120 8.21 24.6 0.246 4 2.5 2.6 0.8 0.21 10.1 11.3 140 5.09 21.6 0.216 6 3.0 2.6 0.8 0.21 10.6 12.0 165 3.39 19.5 0.195 10 3.9 2.6 0.8 0.21 11.5 13.0 220 1.95 16.7 0.167 16 5.0 2.6 0.8 0.26 12.6 14.0 290 1.24 14.2 0.142 25 6.4 2.9 1.0 0.26 14.4 16.4 430 0.795 13.1 0.131 35 7.7 2.9 1.0 0.31 15.6 18.1 540 0.565 11.6 0.116 50 9.2 2.9 1.0 0.31 17.2 19.7 670 0.393 10.2 0.102 70 11.0 2.9 1.0 0.31 18.9 21.7 880 0.277 8.9 0.089 95 12.5 2.9 1.0 0.31 20.5 23.4 1100 0.210 8.5 0.080 120 14.2 2.9 1.2 0.31 22.1 25.7 1380 0.164 7.5 0.075 150 15.8 2.9 1.2 0.31 23.8 27.4 1660 0.132 6.9 0.069 185 17.5 3.2 1.2 0.31 26.0 30.0 2010 0.108 6.7 0.067 240 20.1 3.4 1.4 0.31 29.0 33.7 2670 0.0817 6.4 0.064 300 22.5 3.4 1.4 0.31 31.4 36.4 3170 0.0654 5.9 0.059 400 25.8 3.4 1.4 0.31 34.8 40.0 4150 0.0495 5.2 0.052 - (a) = for information, indicative only

|

|

|

|

|

|

Impact Resistant |

Highly Flexible |

UV Resistant |

Ozone Resistant | Abrasion Retardant |

Cold- resistant |

|

|

|

|

|

|

Resistance To Soldering Heat |

Acid&Alkaline Resistant |

IRM 903 Fuel Oil Resistant |

IRM 902 Mineral Oil Resistant |

Fire Retardant NF C32-070-2.2(C2) IEC60332-3-24/EN50266-2-4 |

Flame Retardant NF C32-070-2.1(C1) IEC60332-1-2/EN50265-2-1 |

|

|

|

|

Low Toxicity NF X70-100/NF F63 808 TM1-04/BS 6853 |

Low Corrosivity IEC60754-2/EN50267-2-2/3 NF C32-074/VDE 0472-813 |

Low Smoke Emission IEC 61034-2 / EN 50268-2 NF C32-073/VDE 0472-816 |

Zero Halogen IEC 60754-1/EN 50267-2-1 NF C32-074//VDE 0472-815 |